Flexibound Books & Flexibinding

What are flexibound books?

Flexibound books, also known as flexibinding is a bookbinding style that sits between paperback binding and hardback binding in terms of its structure and cost to manufacture.

The cover is made with a flexible card stock, rather than a rigid binding board, meaning that the end result is a lightweight book with a flexible cover.

The finished cover overhangs the book block, so the general appearance is similar to a hardback. In fact all production stages up to the casing-in process are the same as a hardback including sewn sections, affixing endpapers, the option of adding head and tail bands, all of which gives the end result an inherent strength.

We offer a product development consultation and free quotation service.

What are the benefits of flexibinding?

Cost

Flexibinding is less expensive than hardback binding, but offers a higher perceived value than a conventional paperback

Flexible

Flexibound books are flexible to handle like a paperback, but the addition of endpapers and head and tail bands gives added strength and durability

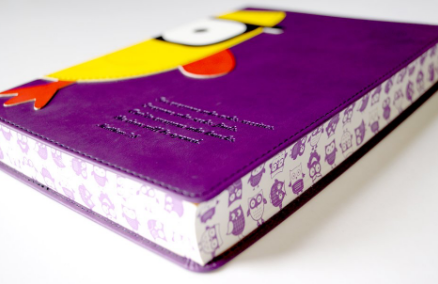

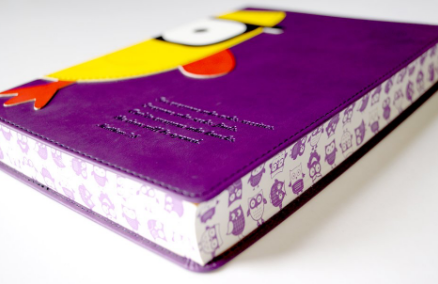

Variety of Materials

Flexibound books can be bound using a wide variety of cover materials such as real cloths and imitation cloths, leathers and PUs and, of course, regular coated papers. Embellishments such as flaps and rounded corners are also possible.

Convenient to Use

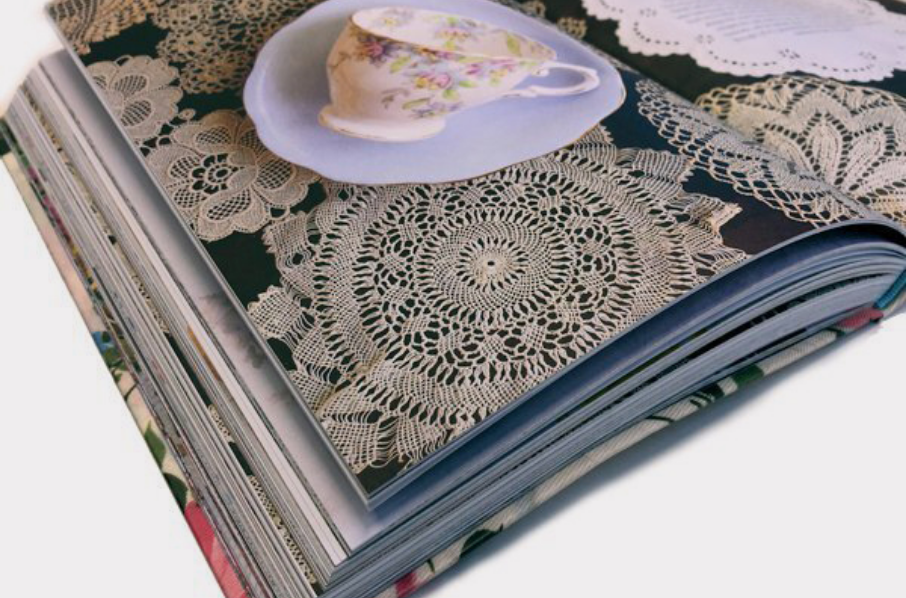

Flexibound books are lighter in weight than hardback books and they lie flatter than a paperback binding, both of these factors make them very convenient to use, especially if the book is intended to be written in.

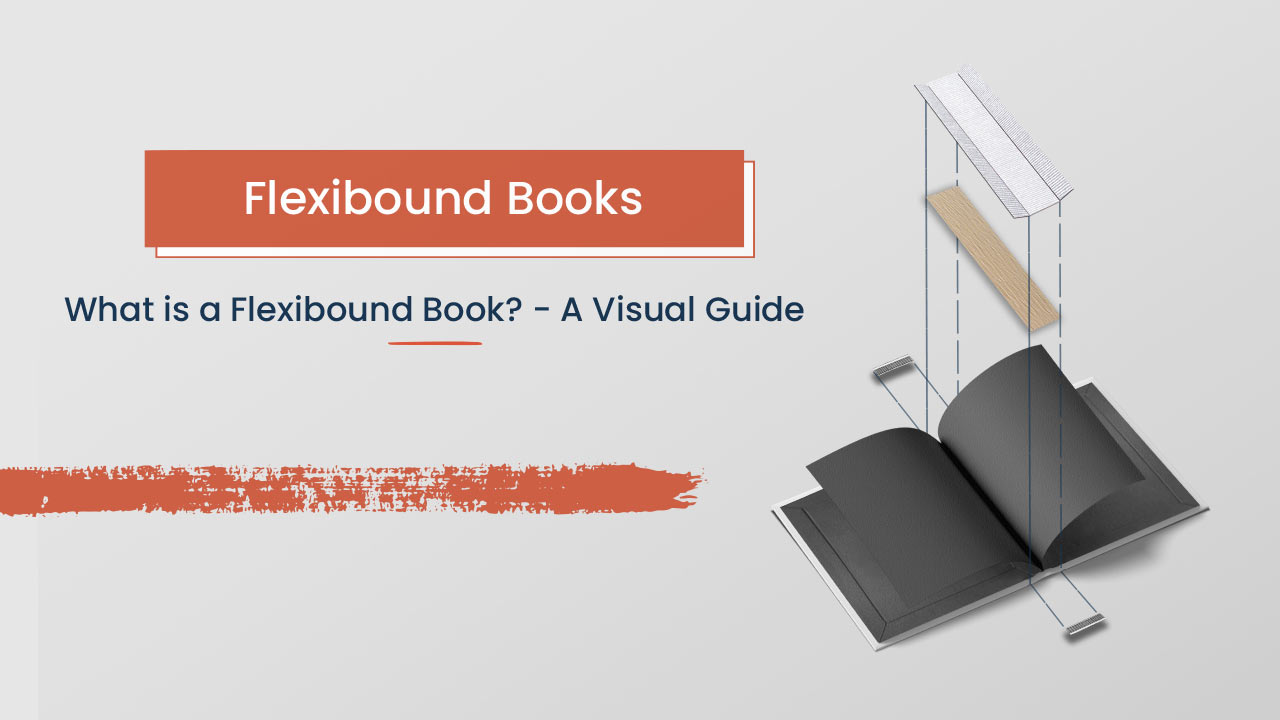

What is a Flexibound Book? – A Visual Guide

Find out more about how flexibound books are made with our visual guide. Our infographic provides a quick and easy overview of our knowledge and expertise in flexibinding.

Different uses of Flexibound Books

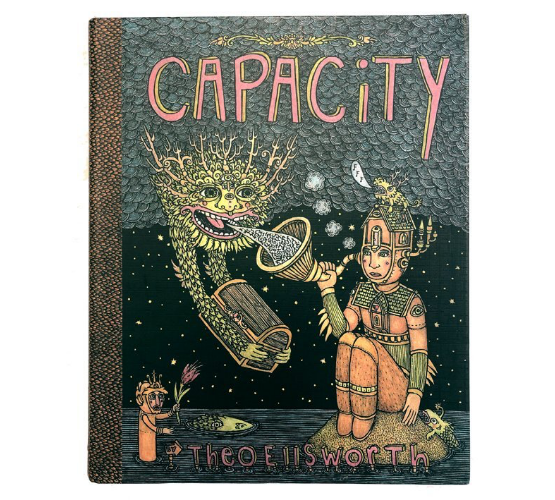

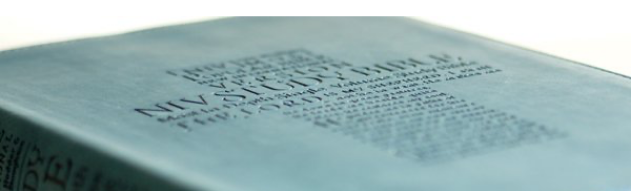

Flexibinding was originally developed for binding Bibles and today most Bibles still have ‘flexi’ covers. We have produced some innovatively designed Bibles which use a variety of materials and finishes in really creative ways.

The format lends itself equally well to cookery titles, field, and travel guides where flexibility is key but something more durable than a paperback cover is called for. This binding style is also good for journals because the book block lies flatter than on a paperback, so it can be written in more easily.

Flexibinding – The Technical Details

Flexibound Covers

The cover of a flexibound book is made from an artboard – which is the same material used on paperback covers, however, the cover is die-cut and folded over and endpapers are then glued to the inside, just as with a cased book. It is generally considered best practice to use a C2S (a board that is coated both sides) rather than a C1S (coated one side) as it gives more flexibility to the end result. Usually, the spine is rounded and head and tail bands can be affixed as a design detail – although this is entirely optional!

How are flexibound books produced?

The actual production process of a flexibound book is similar to that of a cased book, with the main difference being the use of artboard for the cover, rather than rigid grey binding boards with a paper laminated case (PLC). As such, flexibinding is always done on a casing-in machine and never on a paperback line.

There are two different varieties of flexibinding with slightly different methods :

- The first involves printing straight onto the cover artboard which is then die-cut to allow the edges to be folded over. Endpapers are then glued over the inside cover.

- The second version is when you are using a different material for the cover – for example, a PU or a cloth or variations thereof! Again a flexible artboard cover is used but, as it will be covered in your chosen material, it is not printed. A C2S is the best choice for flexibility. There is no die-cutting and folding on this version, the cover is just cut to size, and the material wrapped around, glued in place, edges folded over and endpapers glued inside.

With both versions, the resulting book is lightweight, great to use, and has a high quality feel.

The additional benefits of Flexibound Books

One interesting “add on” that flexibinding offers over cased binding, is that you can add flaps to the cover – as you might on a paperback. It is of course, also perfectly possible to add a jacket to a flexibound book.

Traditional Bible flexibindings often use latex impregnated boards instead of regular artboard, which provides added flexibility and the cover will not crack with repeated use as you bend it. This is, of course, more expensive than using regular artboard but for a truly high-end job, it is well worth considering.

Board Weights

The maximum weight artboards for flexi-binding are as follows:

C1S (coated one side) – 260-280gsm

C2S (coated two sides) – 350gsm

It is worth noting that a 350gsm C2S is a similar feel in weight to a 260gsm C1S – the process of coating both sides of the paper compresses the card so despite the weight being more it can feel thinner.

Start your project

Imago would be delighted to work with you on your next print project. Get in touch with the team to discuss your ideas, no matter how out of the box they might seem!

Why choose Imago for flexibinding

Our expertise, experience, and access to global suppliers make Imago the ideal choice when searching for flexibound book production and print management solutions.

We work with you collaboratively to bring your project to life, and always ensure that your product is manufactured to the highest possible standards both ethically and responsibly, whilst remaining cost-effective.