Paperback Books

What is Paperback Book Printing and Binding?

Often referred to as limp, softcover or softback, paperback book printing and binding is used to create books that have a paper or card cover joined at the spine to the content pages. The cover is usually trimmed flush with the book block

Paperback binding is a more economical option than hardback binding as it involves fewer binding processes, and it is very versatile.

There are several different types of paperback bindings available, the most common are:

- Thread Sewn Paperback – the folded sections of the book are sewn and collated, like a hardback binding, prior to being glued into the cover.

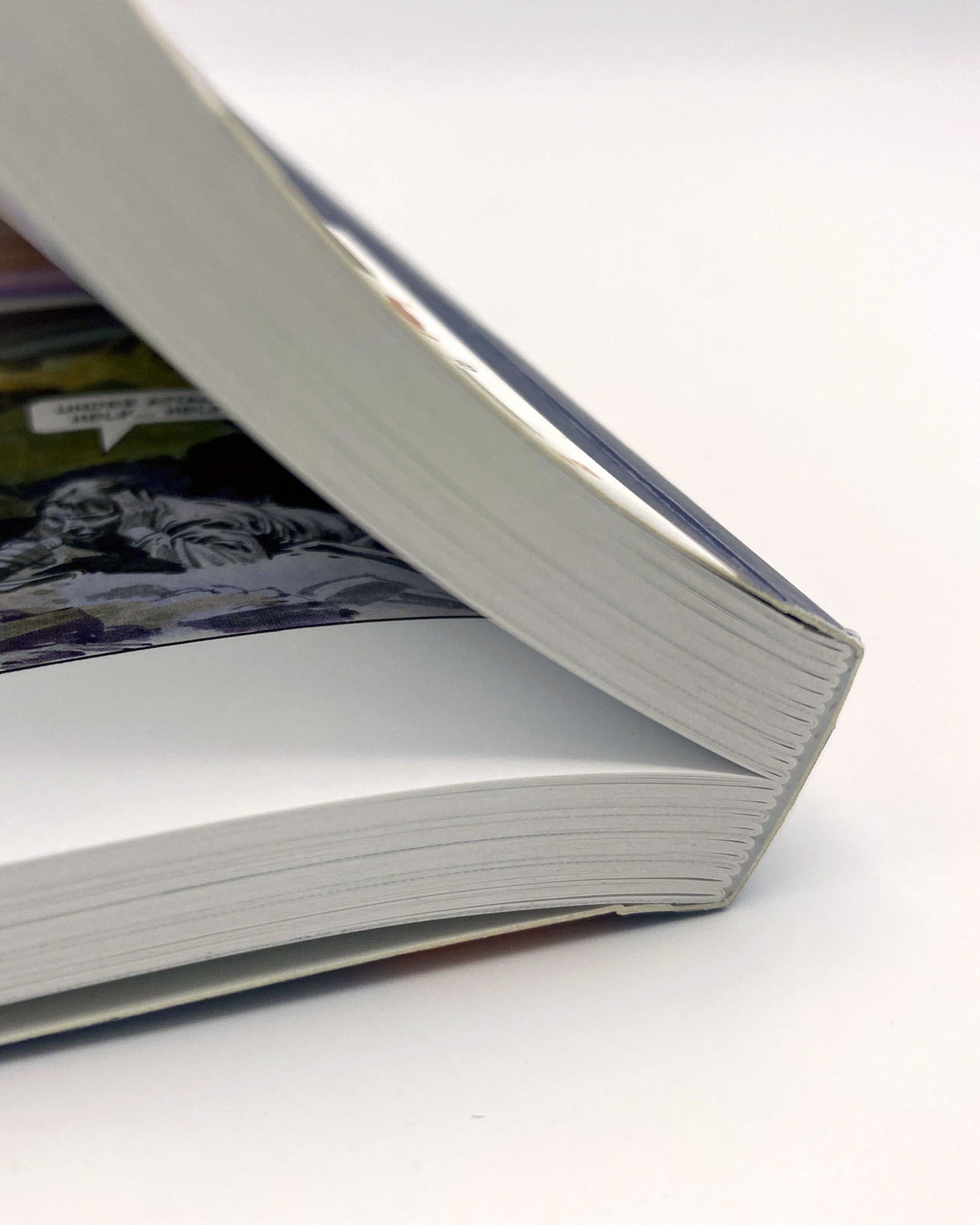

- Perfect bound or Unsewn binding – the backs of the sections are trimmed, or milled off before the pages are bound together and attached to the cover spine. Traditionally uses a flexible EVA glue.

- PUR bound – as Perfect bound, but specifically using a Polyurethane Reactive (PUR) glue

- Wire-stitched – Also referred to as saddle-stitched, is the simplest binding style whereby the cover and contents are stapled together using 2 or 3 metal staples

We offer a product development consultation and free quotation service.

How is Each Paperback Binding Type Used?

Thread Sewn Paperback

this is the strongest paperback binding and has greater resistance and durability than unsewn binding. Suitable for books which are intended to last and require a high-quality finish. Suitable for cookery and other reference books, children’s picture books, educational texts.

Perfect Bound

Perfect binding is fast and inexpensive to produce. Good for books, such as novels, which are generally read once and are not expected to last indefinitely. Also used for monthly magazines or brochures and catalogues.

PUR Bound

To all intents and purposes PUR binding has the same uses as Perfect bound, but the Polyurethane Reactive (PUR) glue is widely considered to be superior in strength and is more flexible than EVA. Pages are less prone to being pulled out and the glue is also more stable and less likely to crack.

Wire Stitching

Fast and inexpensive and pages lie flat when opened. Used for magazines and brochures, children’s sticker and activity books, although not suitable for children under 3 because of the staples can become a sharp point and/or small parts hazard. There are limits to the number of pages that can be wire-stitched (depending on the thickness of the paper) and the number of pages must be divisible by 4.

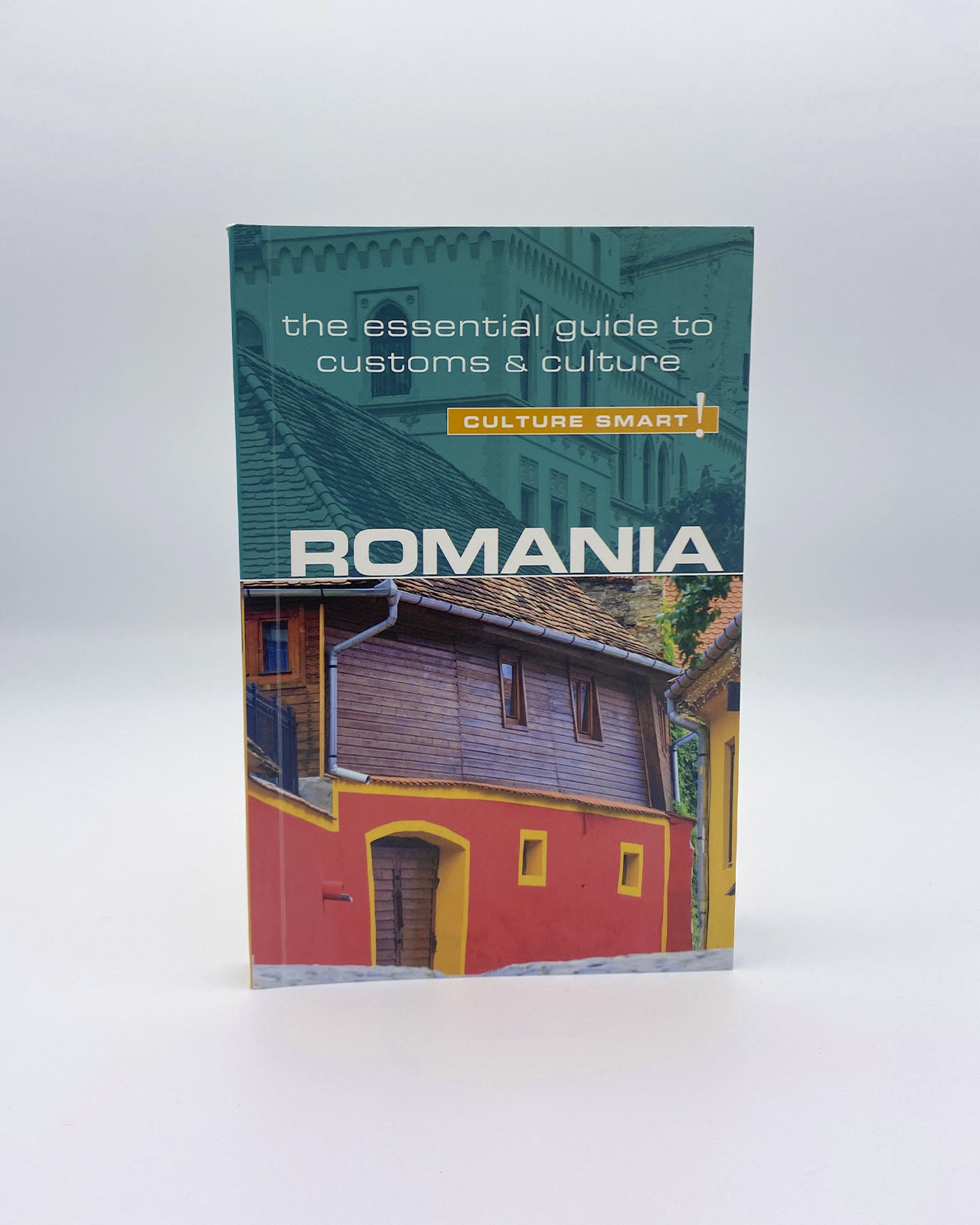

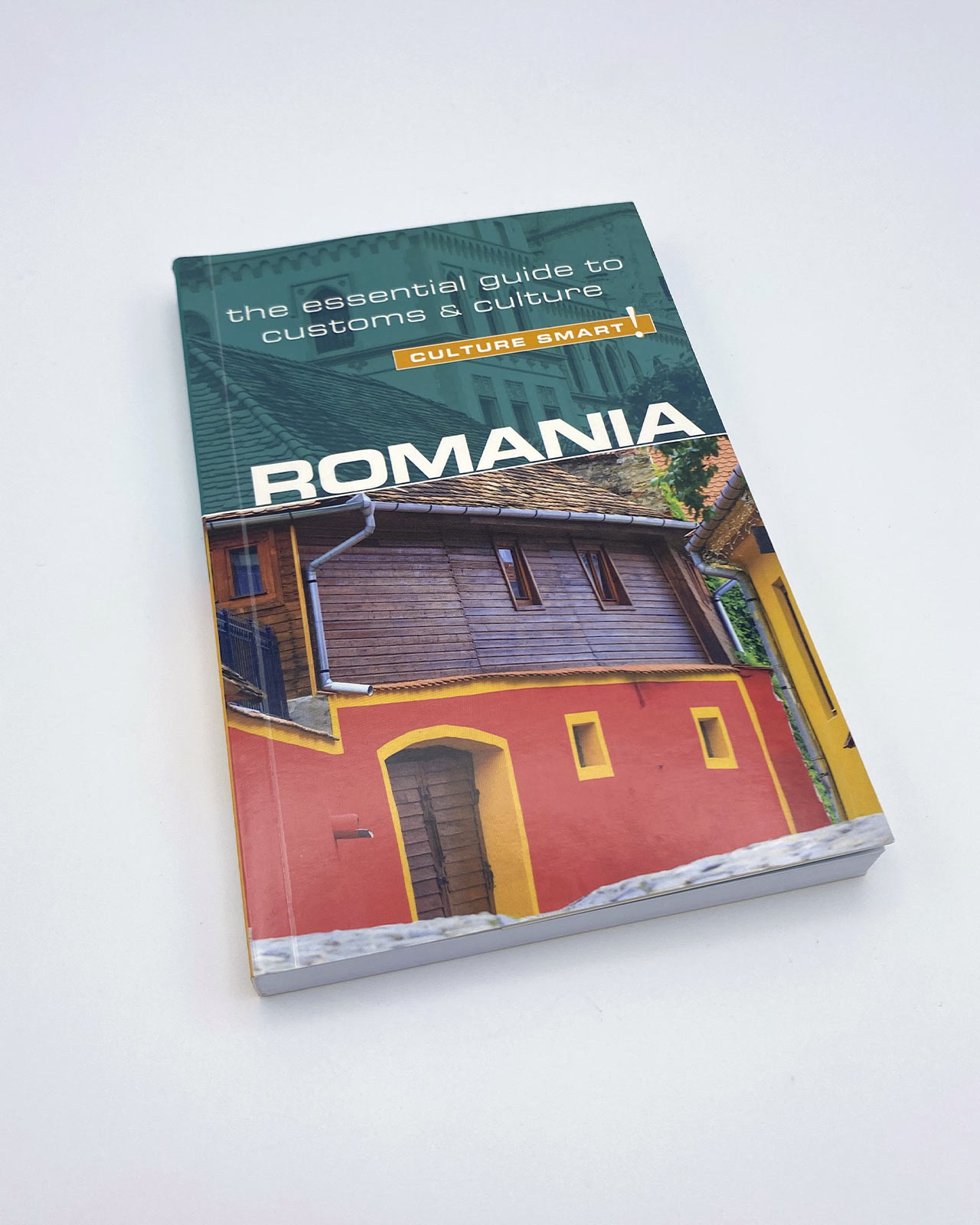

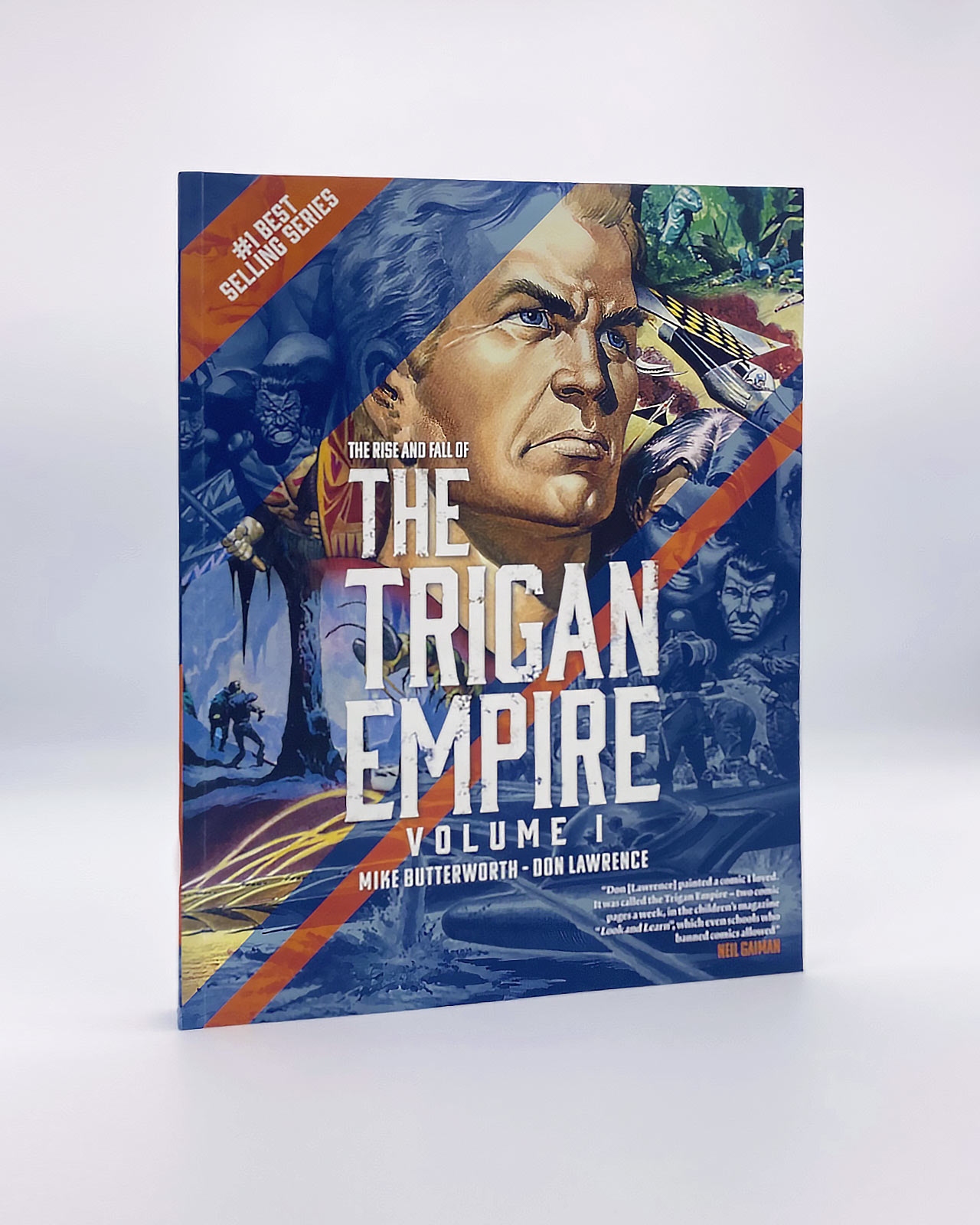

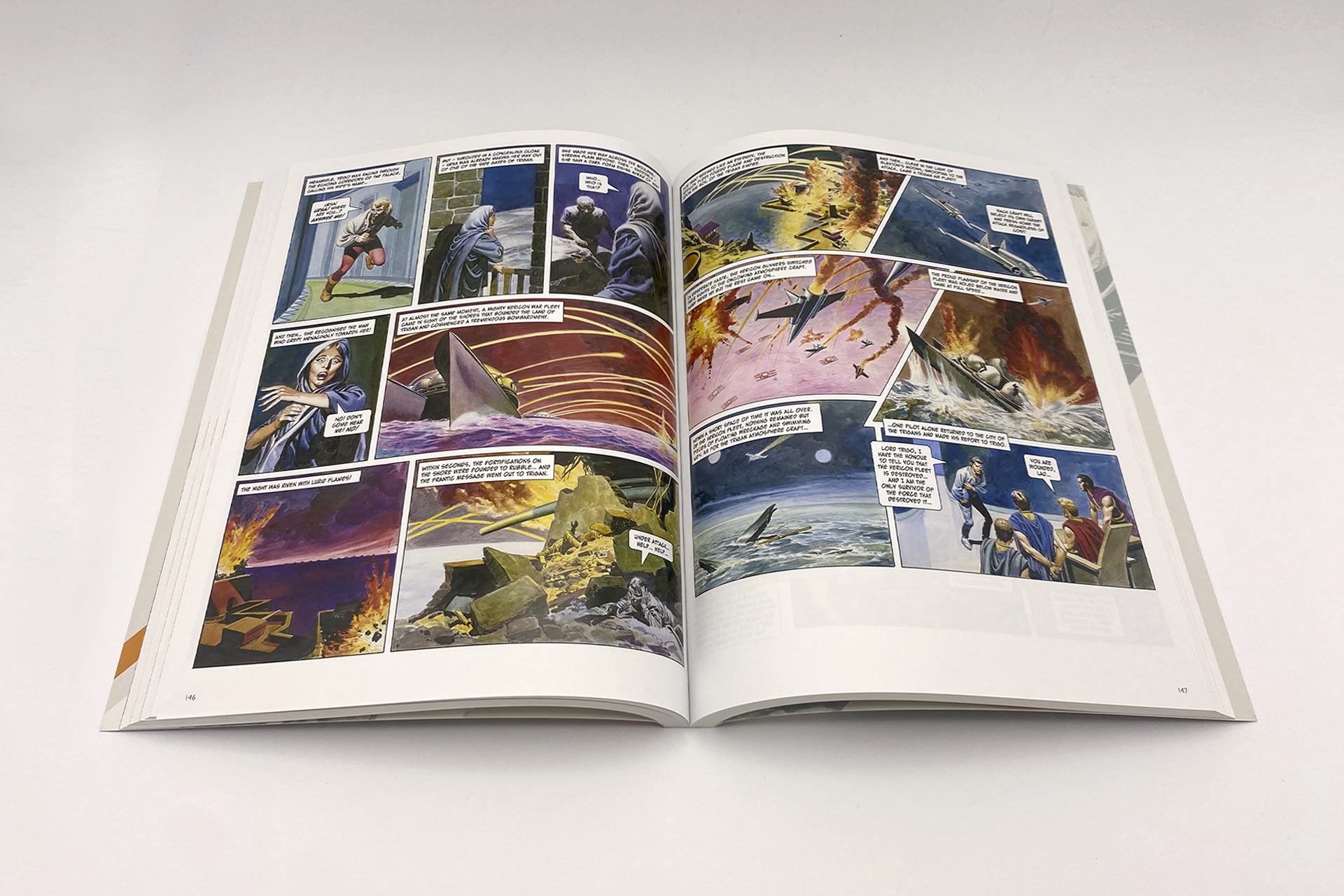

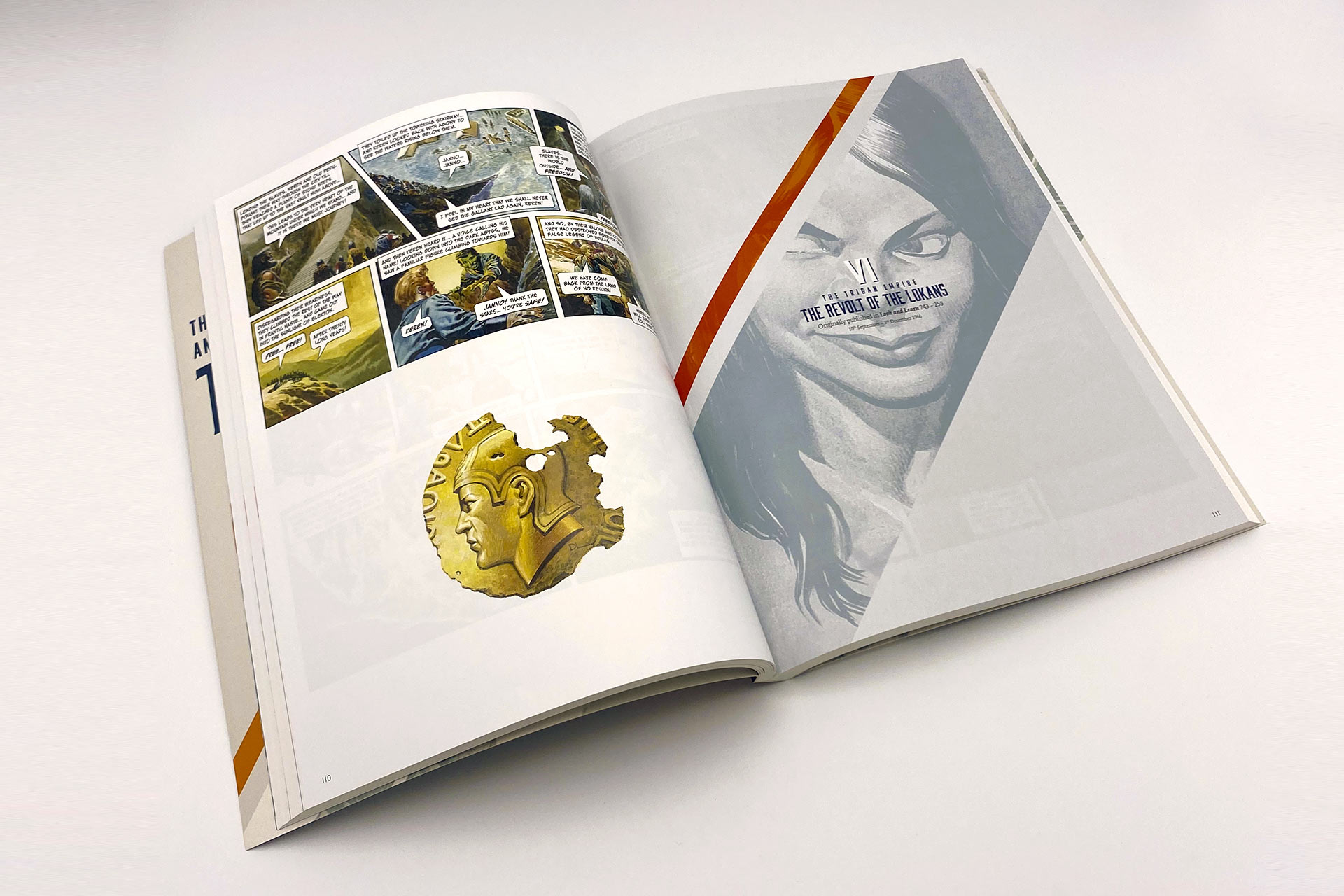

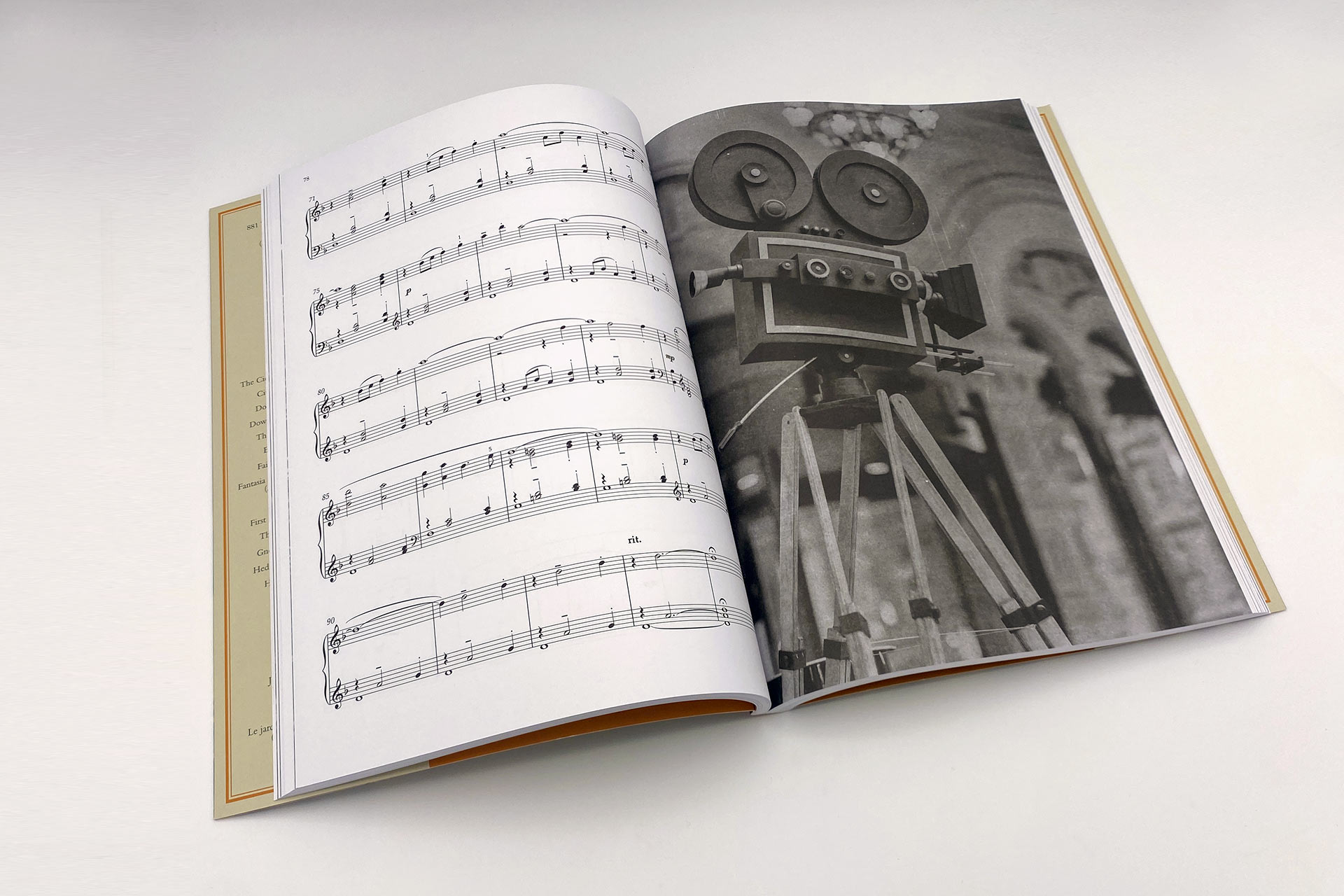

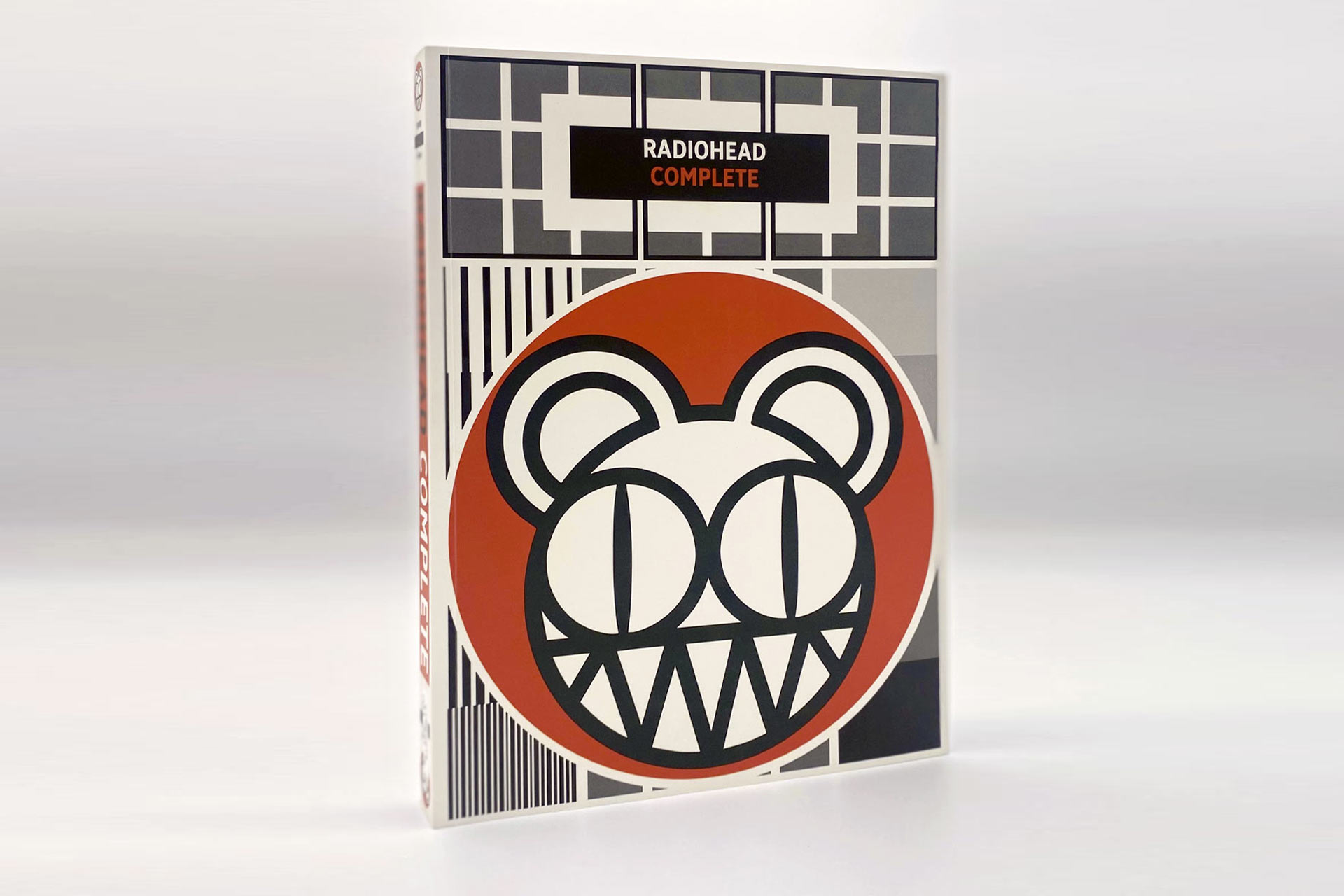

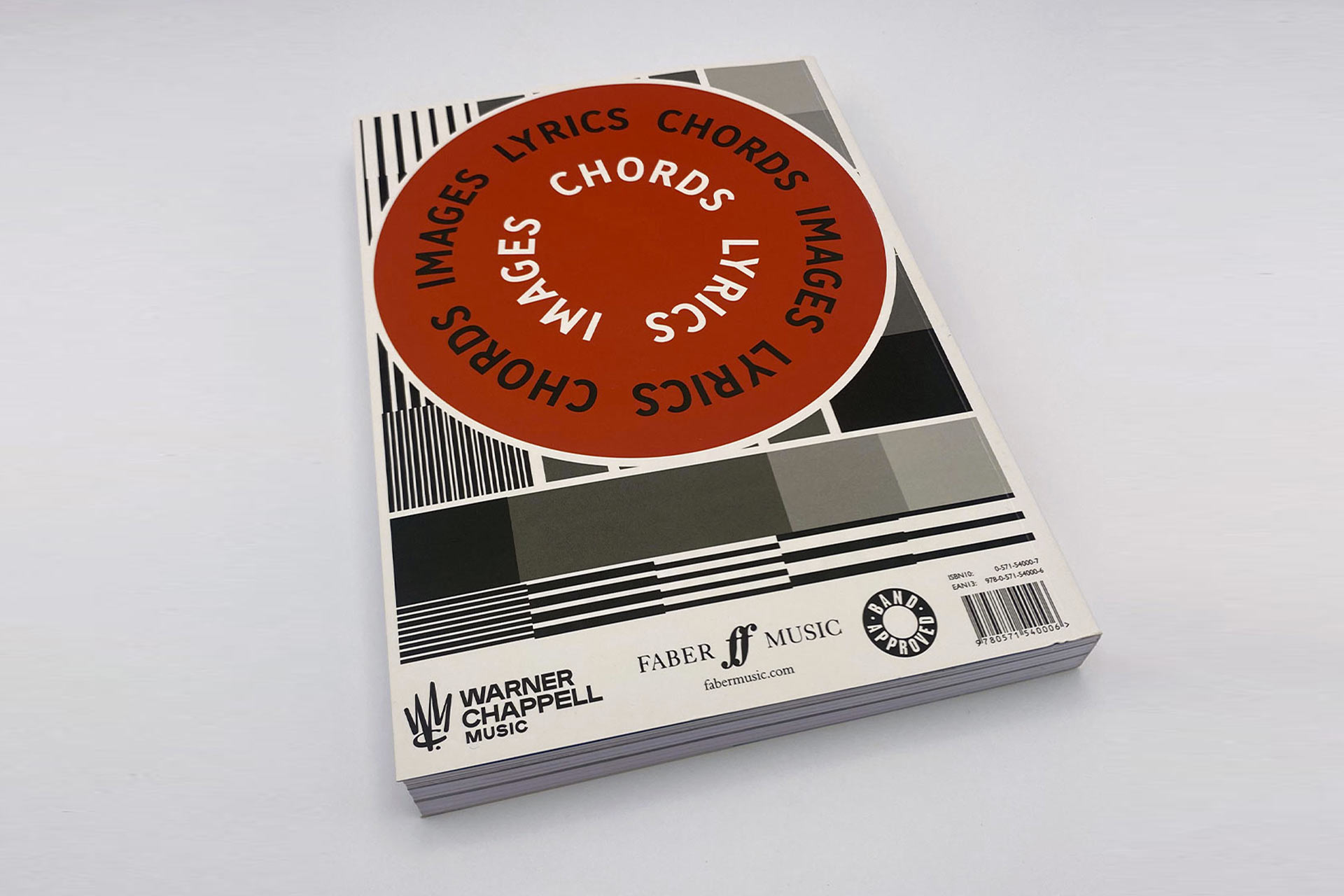

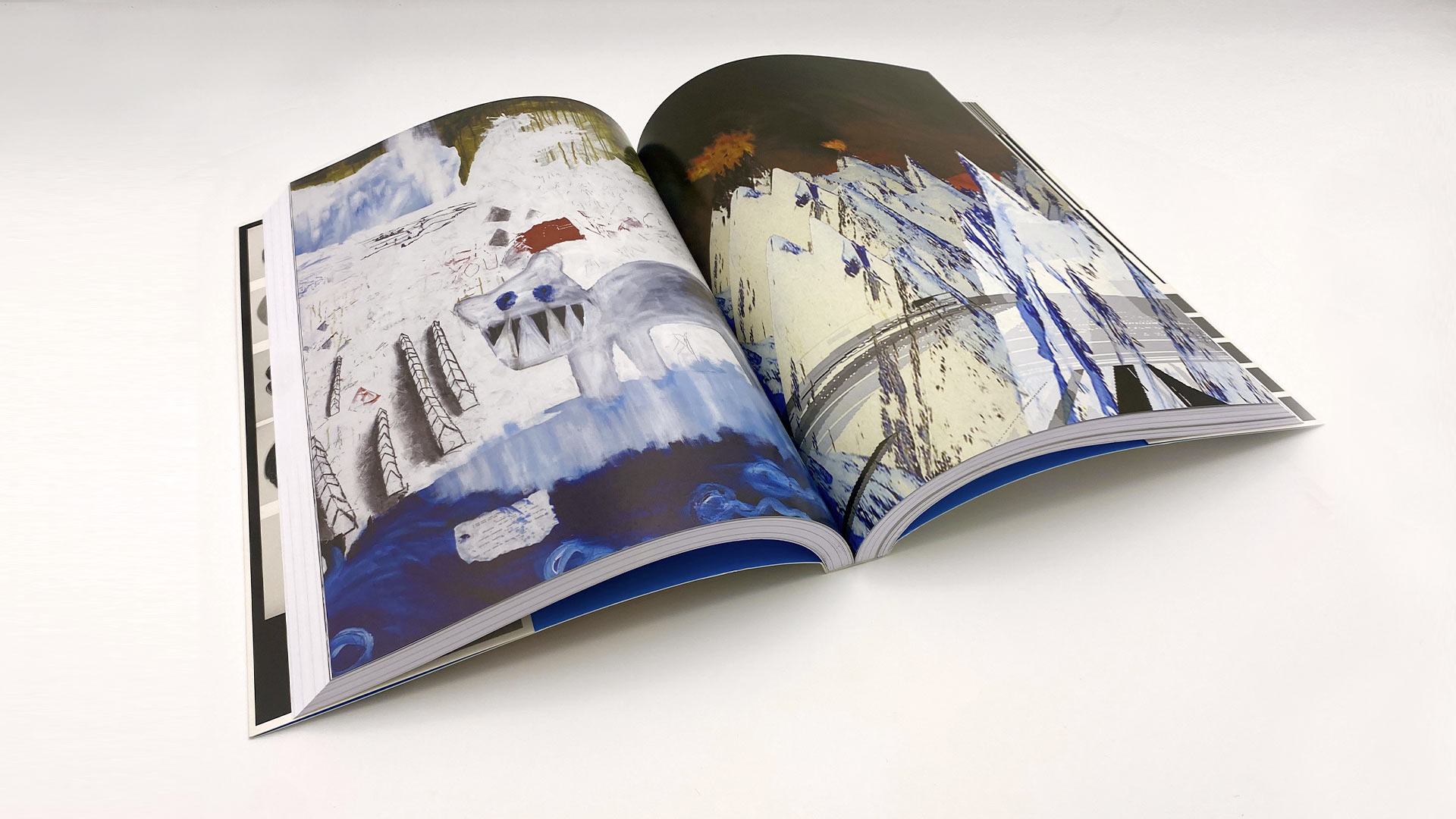

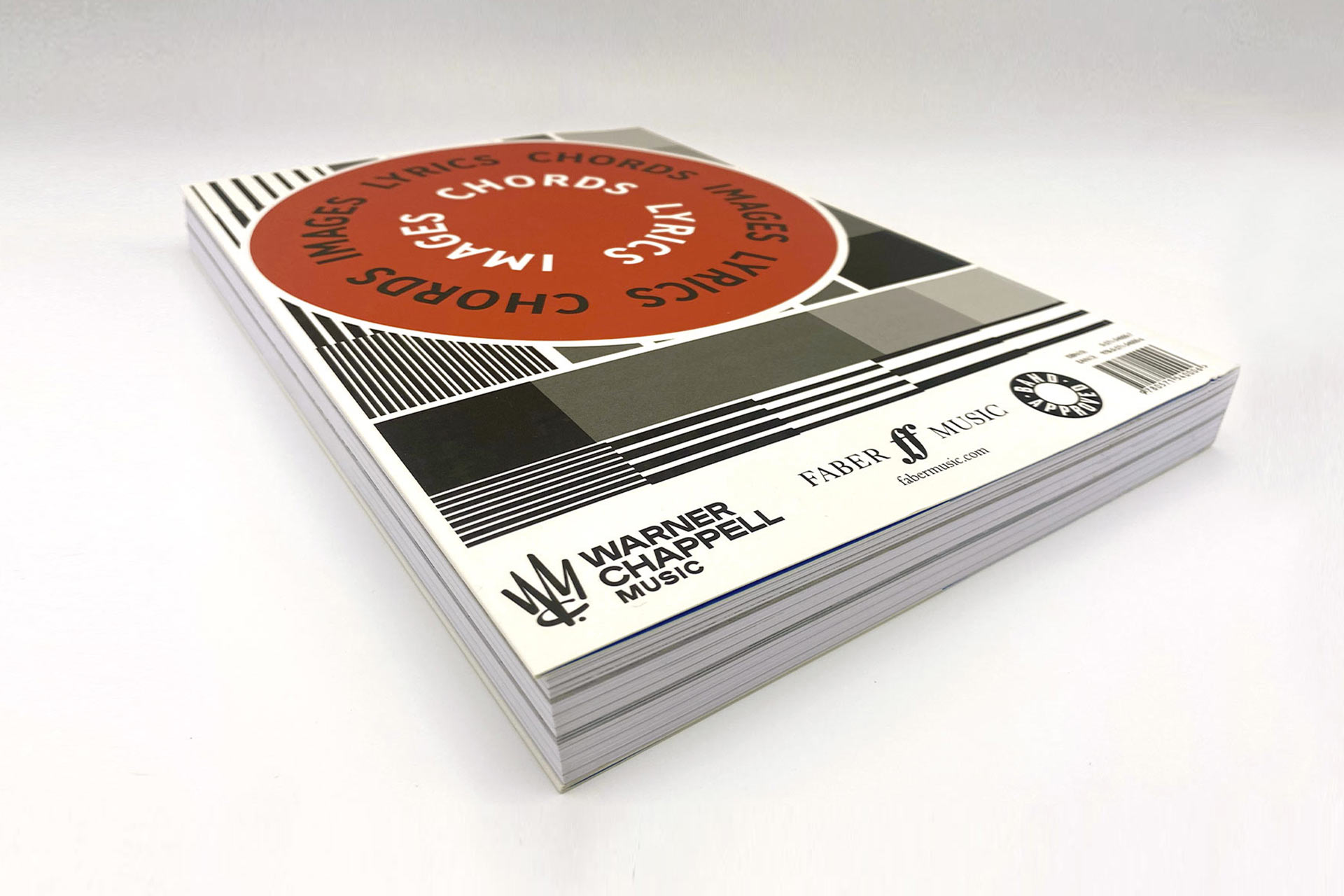

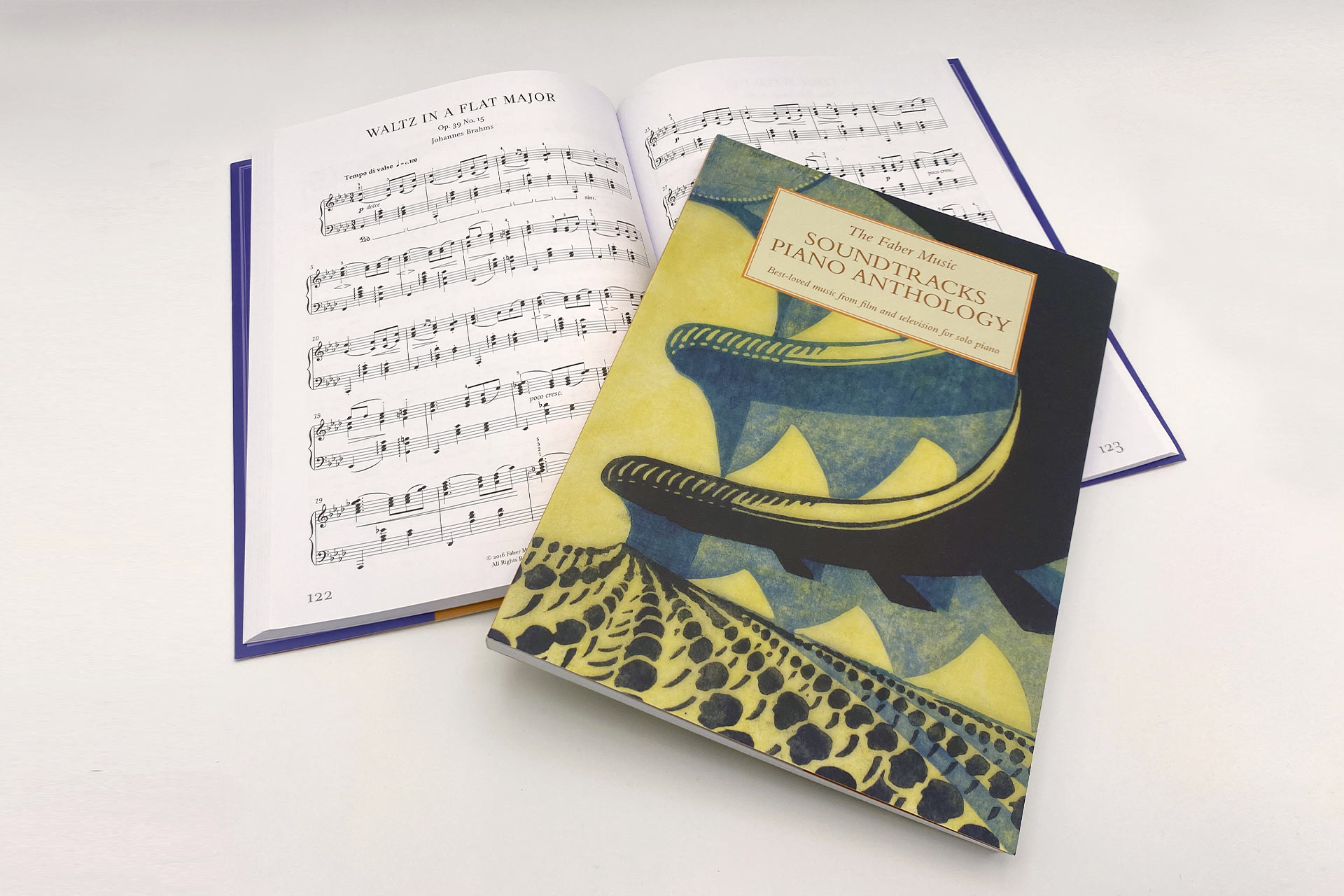

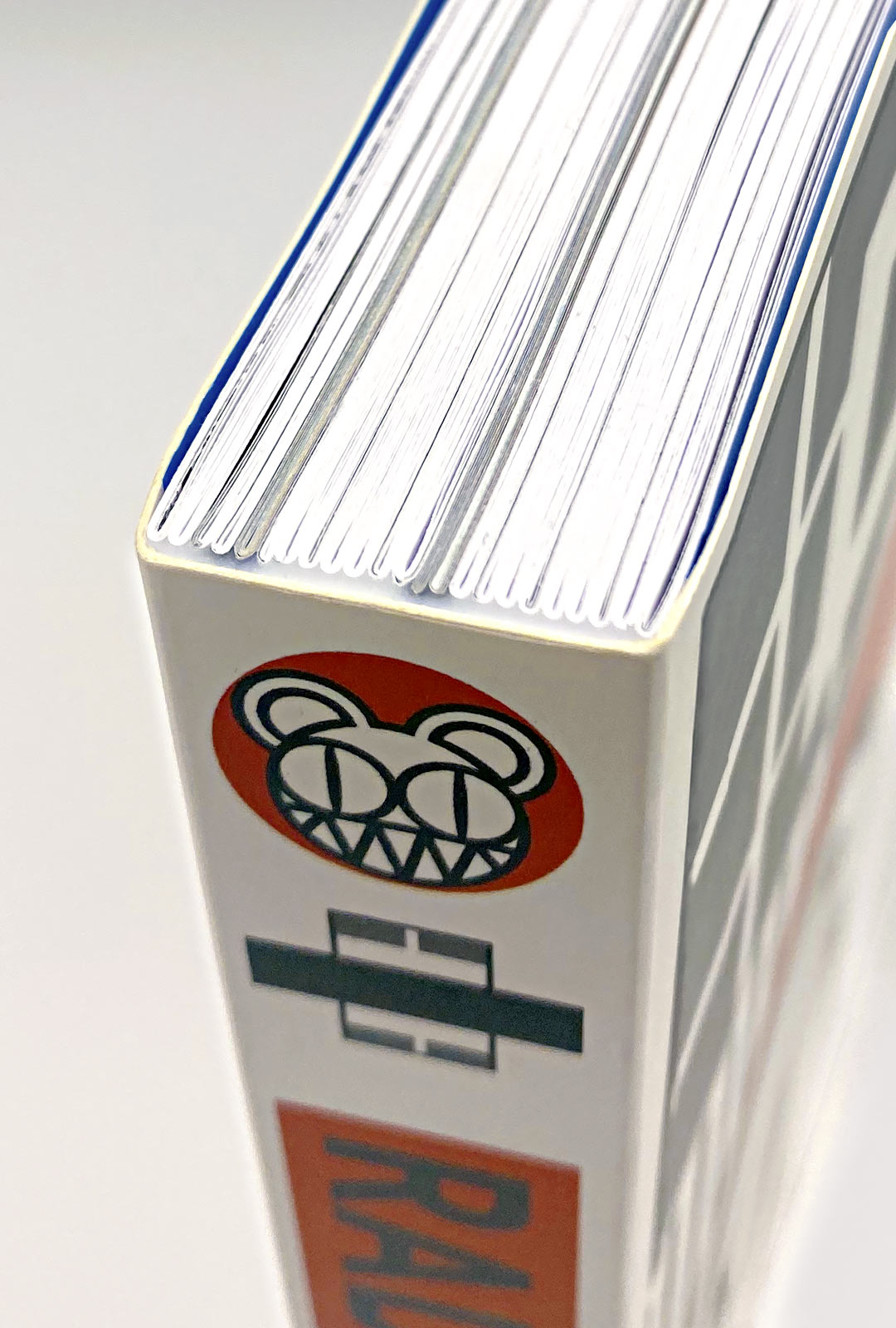

Examples of Paperback Book Printing and Binding

Paperback Book Printing and Binding – The Technical Details

How are Paperback Books Printed and Produced?

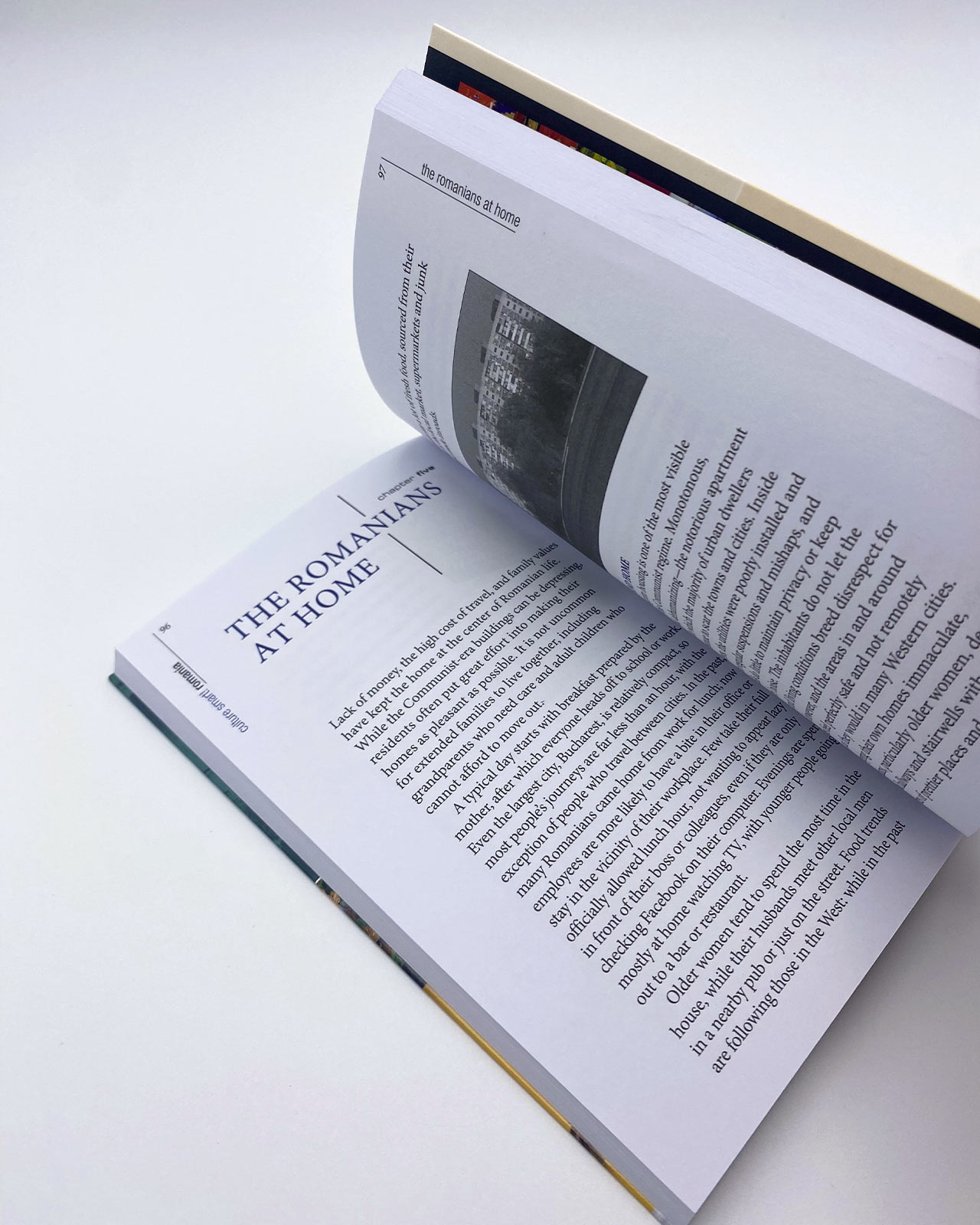

The content pages of a paperback printed book are printed separately to the cover and are folded into sections which, in the case of a thread-sewn paperback, are sewn and collated into a book block.

For unsewn bindings such as perfect or PUR binding the back of the sections are ‘milled’ off and are not sewn. This preparation leaves a ‘roughed up surface’ which absorbs the glue. Some of our suppliers, though not all, are able to offer notch binding whereby the spine is prepared with small notches removed which increases the amount of glue that be applied without seepage and therefore adds strength.

Paperback book printing usually involves a cover that is printed on a coated artcard with lamination or varnish and any other finishes on the printed side.

Covers

The covers are usually printed on a coated board (C1S) and common weights range between 260gsm – 320gsm. Finishes can include gloss or matt lamination, spot UV, and foiling.

Hinge Scores

Imago’s standard process with thread sewn and unsewn paperback book printing and binding is to add a hinge score 6mm from the spine on the front and back and to extend the gluing area to match the hinges.

This creates a stronger bond between the cover and the contents and allows the book to open more easily. Once the cover is drawn on the covered book block is trimmed flush.

The process for wire-stitching is different. The double-page spreads are inset within each other before the cover is drawn, wire-stitched, and trimmed.

Paperback Book Finishing

Imago are able to offer many other options for your paperback book printing project. These include:

- Paperback covers with jacket flaps to provide extra room for a bio or blurb

- Rounded corners to both the cover and the contents

- Die cut shapes and holes in the book cover

Binding Limitations

The different types of paperback binding have varying limitations that you should be aware of before you start your project.

Minimum Pagination & Spine Width

There is a minimum spine width for thread sewn, perfect, and PUR bindings. Low page counts (under 32 pages) using lightweight paper are not viable. Occasionally, we will need to use a heavier paper stock, depending on the factory’s equipment, in order to achieve a particular spine width.

Maximum Pagination

Conversely, with wire-stitched binding, there is a maximum number of pages that can be bound depending on the paper weight being used. Generally speaking, it is not advisable to wire-stitch a publication that is over 64 pages, the thicker the booklet the less flat it will lie. Again, we may need to adjust the paper weight to arrive at a workable solution.

Creep

With wire-stitching there is also a phenomenon called ‘creep’ whereby the pages at the centre of your publication will be narrower than the pages at the start and finish.

Why does Creep Occur?

This is because the pages are inset, so the pages at the centre, if left untrimmed, would extend beyond the cover. So be careful when designing that nothing important is going to get trimmed away – it’s advisable to allow keep important information and designs away from the page edge.

Start your project

Imago would be delighted to work with you on your next print project. Get in touch with the team to discuss your ideas, no matter how out of the box they might seem!

Why choose Imago for Paperback Book Binding?

Our expertise, experience, and access to global suppliers make Imago the ideal choice when searching for paperback book printing, limp binding and production management solutions.

We work with you collaboratively to bring your project to life, and always ensure that your product is manufactured to the highest possible standards both ethically and responsibly, whilst remaining cost-effective. You can take a look at some of our paperback book printing projects by checking out our in-depth case studies.